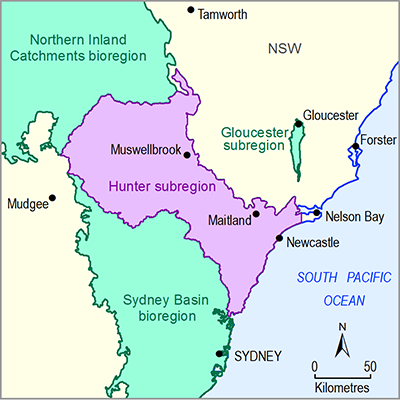

Mining relieves in situ stresses in the surrounding rock mass, causing deformation including fracturing. For example, in parts of the active caving zone of longwall mines, total strains can easily exceed 100%. The strain increments naturally alter the hydraulic properties of the surrounding rock, and it is generally assumed that the conductivity will increase by orders of magnitude in both the horizontal and vertical directions (Adhikary and Wilkins, 2012). This is because rock plastic deformation dilates existing micro and macro fractures and creates new ones. The rock-mass conductivity after caving and consolidation can be inferred from the response of piezometers or the measurement of water or gas flows within, above and below the goaf (Guo et al., 2014). It is always higher than the in situ value. This is the reason that the water make in a typical longwall mine will increase as panel width (and conductivity changes) increases, and, conversely, why a typical bord-and-pillar mine (with essentially very thin and short panels) makes less water than a typical longwall mine. Therefore, in the Hunter subregion groundwater model, the hydraulic conductivity of rock units above and below each mine working is assumed to be different from the in situ value.

In the Hunter subregion groundwater model, the hydraulic conductivity, K, above and below each mine working (i.e. above the polygon superimposed upon the seam disc), is enhanced according to:

|

|

(5) |

where K0 is the base conductivity (both horizontal and vertical components), determined by layer number, lithology and depth, as described in Section 2.6.2.3; and Δ parameterises the conductivity change. Δ = 0 before mining of the seam commences, and Δ = Δ(h) at height, h, above the seam immediately after mining commences. This conductivity enhancement is assumed to remain after mining ceases, thus a separate ‘active phase’ (with Δ large) and ‘consolidation phase’ (with Δ smaller) above longwall mines is not included in the model (such phases would be important to include if the model were trying to predict mine water makes rather than treating them as an input parameter). However, Δ may be defined differently for each polygon. Δ is calculated using the following piecewise-linear function of the height above the mining seam, h:

|

|

(6) |

|

|

(7) |

|

|

(8) |

|

|

(9) |

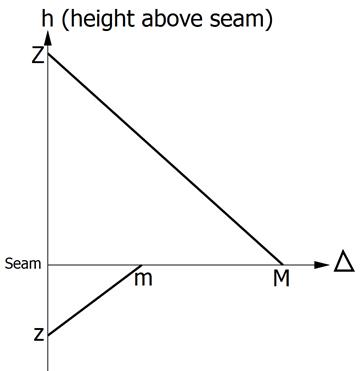

The general form of the relationship is illustrated in Figure 20 where it is clear that conductivity change is M orders of magnitude directly above the seam, and m orders of magnitude directly below the seam, and that the conductivity changes occur between z metres below the seam and Z metres above the seam.

As discussed in Adhikary and Wilkins (2012), longwall mining enhances the permeability greatly compared with bord-and-pillar mines, simply because the rock deformation caused by the latter is comparatively small. The effective conductivity in the immediate roof of longwall mines can be enhanced by up to 10 orders of magnitude. The values M, m, Z and z are varied in the uncertainty analysis around the values given in Table 5 for different mine types. The values in Table 5 are motivated by the numerical, experimental and observational studies performed by Adhikary and Wilkins (2012) and Guo et al. (2014).

The conductivity change (Δ) at a single point can be enhanced by many mine workings in multi-seam mining situations, with each enhancement assumed to be additive. To avoid precision-loss issues in the numerical solver when the hydraulic conductivity is increased by more than 20 orders of magnitude, an upper bound of Δ tot<20 is placed upon the total enhancement. Such large changes could occur in multi-seam mining situations as multiple mining operations contribute additively to the conductivity change.

Table 5 Model parameters for representing hydraulic conductivity enhancements for different mine types

|

Parameter |

Longwall |

Bord-and-pillar |

Open-cut |

|---|---|---|---|

|

M |

9 |

2 |

0 |

|

Z |

500 |

100 |

0 |

|

m |

7 |

1 |

8 |

|

z |

–250 |

–50 |

–90 |

Hydraulic enhancement is implemented in the groundwater model over the maximum footprint area of a longwall mine on the first day of mining. The enhancement is assumed to be permanent.

Product Finalisation date

- 2.6.2.1 Methods

- 2.6.2.2 Review of existing models

- 2.6.2.3 Model development

- 2.6.2.4 Boundary and initial conditions

- 2.6.2.5 Implementation of the coal resource development pathway

- 2.6.2.6 Parameterisation

- 2.6.2.7 Observations and predictions

- 2.6.2.8 Uncertainty analysis

- 2.6.2.9 Limitations and conclusions

- Citation

- Acknowledgements

- Currency of scientific results

- Contributors to the Technical Programme

- About this technical product