The information below is taken from the draft EIS for the China Stone Coal Project (Hansen Bailey Environmental Consultants and MacMines, 2015).

There are six types of water in the water management system (WMS):

- underground mine pit water – comprised of groundwater inflow to underground workings and water recycled from underground operations

- open-cut mine pit water – comprised of groundwater inflow to the open-cut pit and runoff from the pit catchment

- return water from tailings storage facility (TSF) – comprised of water recovered from tailings slurry afters the solids have settled out of the mixture in the storage facility, rainfall and runoff from the contained TSF catchment and runoff from the power station waste storage area

- runoff from disturbed areas – also includes overburden emplacement areas and mine infrastructure areas

- runoff from areas affected by mine subsidence

- runoff from areas unaffected by project activities.

2.1.6.4.1 Underground mine pit water

Modelling has estimated peak groundwater inflows to the Northern Underground to be 1410 ML/year at year 16 and the Southern Underground 1520 ML/year at year 13. The actual amount of dewatering will be reduced due to evaporation and infiltration to the pit walls and floor. It has been estimated that up to 250 ML/year of underground supply water will be recycled from each operating longwall. This will be collected in sumps along with groundwater inflow.

Underground pit water will be pumped to the surface and stored on site for reuse. Both the Northern and Southern underground will have pit water dams in their respective mine infrastructure areas (MIAs). Water from the pit water dams will be pumped to a dedicated Mine Water Dam for storage and reuse as mine water supply. The pit water dams will have nil catchment and will be operated to ensure nil overflow.

2.1.6.4.2 Open-cut mine pit water

Modelling has estimated peak groundwater inflow rates to the open pit to be 4070 ML/year. Evaporation, surface wetting and infiltration to the pit walls and floor will reduce the volume of dewatering.

The pit catchment area includes the active pit area as well as any areas of overburden emplacement and areas above the highwall that cannot be diverted around or away from the pit. The pit catchment will progressively increase as the mine develops. A series of temporary and permanent diversions and drains will be constructed to minimise the generation of mine affected water from rainfall-runoff.

Open-cut pit water will collect in sumps in the floor of the active pit. It will be pumped to a series of four open-cut pit water dams located along the length of the open-cut mining area. Water from these dams will then be transferred to the Mine Water Dam for storage and reuse. The pit water dams will have nil catchment and will be operated to ensure nil overflow.

During high rainfall events the open-cut pit will collect significant volumes of water. To allow for continued operation of the mine this water will be discharged under controlled conditions.

2.1.6.4.3 Return water from tailings storage facility and power station waste storage facility

The TSF will develop progressively over the 50 year project life and will cover 603 ha when complete. The TSF catchment area will be isolated first by temporary diversion drains and then by an embankment around the perimeter. The power station waste storage facility (PSWSF) will also develop progressively over the first ten years of the project and will cover 80 ha when complete. The PSWSF catchment will also be isolated with perimeter diversion drains.

Tailings slurry will be pumped from the CHPP to the TSF. Tailings solids will settle out within the TSF and supernatant will collect in a decant pond within the TSF. Rainfall-runoff will also collect within the decant pond.

The PSWSF will be developed by trucks placing dry power station waste, similar to an out-of-pit overburden emplacement. Surface runoff from the PSWSF will drain to internal sumps and then be pumped to the adjacent TSF.

A perimeter seepage collection drain will collect any seepage from the TSF and PSWSF. This will be pumped to the TSF decant pond.

Water from the TSF decant pond will be pumped to the return water dam. The return water dam will be a primary water supply for the CHPP.

2.1.6.4.4 Runoff from disturbed areas

Diversion drains will be installed upstream to divert overland flow away from overburden areas. Based on the overburden leach test results overburden leach in rainfall-runoff will be suitable for passive drainage from the site. As runoff from rehabilitated overburden areas is likely to have high sediment load, runoff from these areas will be directed through sediment dams prior to discharge from the site. Rehabilitated overburden areas will generate clean runoff which will be allowed to drain passively from the site.

In the MIA runoff will be isolated by diversion drains and/or bunding. Runoff from these areas will be directed through sediment traps (and oil separators where hydrocarbons are potentially present) and collected in a catch dam. Water from catch dams will be transferred to the Industrial Area Dam and used as mine water supply.

2.1.6.4.5 Runoff from areas affected by mine subsidence

Subsidence may cause localised alteration to drainage paths and ponding in shallow surface depressions. This will be mitigated by the installation of minor remedial drainage earthworks.

2.1.6.4.6 Runoff from areas unaffected by project activities

Where possible runoff from undisturbed areas will be diverted around disturbed areas and allowed to drain from site.

Permanent highwall dams and drains will be constructed and these will remain in place after mine closure. Clean runoff from the northern and southern drainage corridors will flow to the headwaters of Tomahawk Creek and North Creek respectively.

The permanent highwall dams will create temporary isolated undisturbed catchments during the operations phase. Temporary diversion drains will be put in place and water collected will be used for dust suppression.

Product Finalisation date

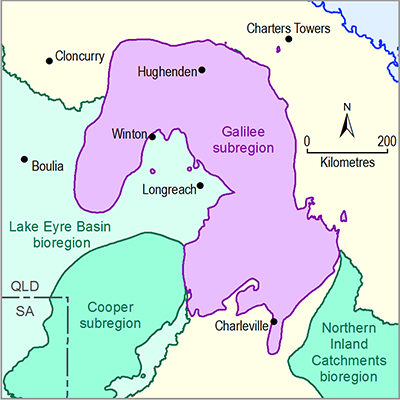

- 2.1.1 Geography

- 2.1.2 Geology

- 2.1.3 Hydrogeology and groundwater quality

- 2.1.4 Surface water hydrology and water quality

- 2.1.5 Surface water – groundwater interactions

- 2.1.6 Water management for coal resource developments

- Citation

- Acknowledgements

- Currency of scientific results

- Contributors to the Technical Programme

- About this technical product