The information below is taken from the Commonwealth EIS for the China First Coal Project (Engeny Water Management, 2013).

Water has been classified into four types:

- contaminated water – surface runoff from the CHPP, ROM and stockpile areas and water contained within open-cut pits. This water is likely to be saline and may be of low pH and may also contain hydrocarbons or other contaminants such as trace metals. This water will be managed to prevent discharge to waterways and to meet on-site water requirements

- dirty water – surface runoff from spoil dumps and rehabilitated areas that could contain sediments but typically not elevated levels of contaminants. This water will be directed to sedimentation dams for settling of suspended solids and reuse on site. This water would only be discharged to receiving waters during significant rainfall events

- clean water – surface runoff from natural catchments. This will not be contained on site and will pass through the site via creek diversions and bunding walls around open-cut pits

- groundwater – water produced through dewatering of underground mine working and aquifer pre-drainage. This is expected to be low salinity (<1500 µS/cm). This water will be reused for underground mining processes, additional supply for raw water requirements and treated as necessary for potable water supply.

The components of the water management system are:

- box cut spoil sediment dams

- pit spoil sediment dams

- environmental dams

- pit dewatering dams

- underground dewatering dams

- clean water dams

- return water dam.

2.1.6.3.1 Box cut spoil sediment dams

These dams will be provided in the box cut spoil areas prior to year 1 of operations. They will retain stormwater runoff to maximise settling of suspended solids and provide water for construction related purposes such as dust suppression. Once the mine commences these areas will be progressively rehabilitated and the sediment load to the catchments will decrease significantly. The good quality water is intended for reuse in underground mining operations.

2.1.6.3.2 Pit spoil sediment dams

These dams will be constructed in-pit for open-cut mining operations. The number of dams required will increase with the progression of the open-cut highwall. The assumption is that spoil areas will be progressively rehabilitated which will improve the runoff water quality. Water in the spoil dams will be used for dust suppression operations. The size of the spoil dams is based on the assumption that the spoil will be non-acid forming and low salinity, the size may need to be adjusted if this is not the case. The dams will be designed to allow removal of suspended sediments through natural sedimentation.

2.1.6.3.3 Environmental dams

Environmental dams will manage contaminated runoff from run-of-mine (ROM) stockpiles, product stockpiles and industrial areas. It is expected that runoff from these areas has the potential to be saline and contain contaminants such as metals and hydrocarbons. Water captured in the environmental dams will be transferred to the pit dewatering dams via the return water dam. Two environmental dams are proposed, one located adjacent to the CHPP and the other adjacent to the second ROM stockpile in the infrastructure corridor.

2.1.6.3.4 Pit dewatering dams

Pit dewatering dams will provide primary storage for water pumped from the open-cut pits. Up until ten years of operations the pit dewatering dams will be located to the west of highwall side of the pits. At approximately 15 years of operations the pit dewatering dams will be progressively relocated to within the spoil dumps to allow progression of mining. It is proposed that there will be four pit dewatering dams. These dams will be ‘turkey’s nest’ design to prevent inflows from the catchment and reduce the risk of overflow.

2.1.6.3.5 Underground dewatering dams

Two underground dewatering dams are proposed. They will store groundwater from aquifer pre‑drainage (to reduce groundwater inflows to underground and open-cut mines) as well as dewatering of underground operations. The underground dewatering dams will be used to supply underground mining operations and raw water requirements. These dams will be ‘turkey’s nest’ construction or with catchment diversion to prevent external catchment inflow and contamination.

2.1.6.3.6 Clean water dams

There will be two 120 ML clean water dams. One will be located next to the coal handling and preparation plant (CHPP) and the other near the underground portals. The dams will hold enough raw water for two weeks of operation of the CHPP and underground mining in the event of pipeline or pump failure. The dams will be ‘turkey’s nest’ construction to prevent contamination from inflows and will be lined to prevent seepage losses.

2.1.6.3.7 Return water dam

The return water dam will manage excess water from the CHPP. The return water dam will be a ‘turkey’s nest’ construction to prevent inflow of catchment water which will reduce the chances of it overflowing.

Product Finalisation date

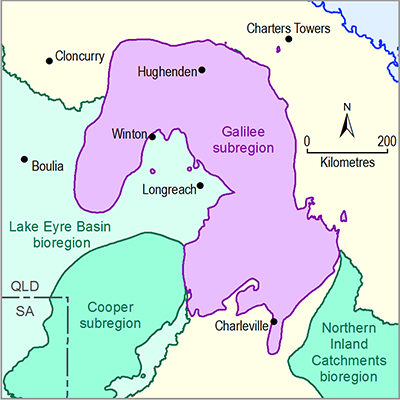

- 2.1.1 Geography

- 2.1.2 Geology

- 2.1.3 Hydrogeology and groundwater quality

- 2.1.4 Surface water hydrology and water quality

- 2.1.5 Surface water – groundwater interactions

- 2.1.6 Water management for coal resource developments

- Citation

- Acknowledgements

- Currency of scientific results

- Contributors to the Technical Programme

- About this technical product