The information below is from the Supplementary Environmental Impact Statement (EIS) for the Alpha Coal Project (Parsons Brinckerhoff, 2011).

The proposed water management system for the Alpha Coal Project classifies water into five types, each with a management system:

- process water management system – managing process water that has been used in the coal handling and preparation plant (CHPP). This includes the tailings storage facility (TSF), decant dam and return water system

- clean water system – separating clean runoff from undisturbed areas, from runoff from the open-cut mine pits and other contaminated dirty water management systems, and diverting it to Sandy Creek and Spring Creek. This type of water has low turbidity and low salinity

- contaminated water management system – managing runoff from the open-cut pits and other areas that could contribute contaminants such as the mine infrastructure area (MIA), CHPP, coal stockpiles and dump stations

- dirty water management system – treating runoff from overburden dumps and other areas that could contain sediment

- groundwater management system.

The systems are discussed in more detail below.

2.1.6.1.1 Process water management system

Wet tailings slurry will be transferred by pipe and pump to the TSF. Excess water in the TSF will be decanted to a separate dam and a pump and pipeline system returns the water to the CHPP for reuse as required.

2.1.6.1.2 Clean water system

The purpose of this system is to minimise the site water inventory and maintain pre-development discharges into Lagoon Creek and Sandy Creek. Lagoon, Sandy and Spring creeks will be diverted around or through the mine site. Levees will be used to prevent waters entering the pit. Dams, levees and additional intermediate diversion drains west of the pit will capture and divert water from undisturbed catchments found up slope (west) of the mine area. Water will only be imported onto site if there is not sufficient water in the contaminated water management system or if high quality water is required for on-site processes. Imported water will be stored in the raw water dam and a pump and pipeline system will deliver this water to where it will be used on site.

2.1.6.1.3 Contaminated water management system

Small sumps in the pit floor will collect and contain local surface water runoff from the pit floor, highwall, low wall and end walls. Pit dewatering pumps and pipelines will transfer pit water to the nearest pit dewatering dam (via a small staging dam if required). A drainage system will convey runoff from disturbed areas to the nearest environmental dam. The environmental and pit dewatering dams have been designed to minimise the areas draining to them which minimises the storage requirements in order to reduce the risk of uncontrolled spilling during rainfall events. A pump and pipeline system will deliver water from these dams to where it will be used on site.

A borefield will be used to minimise groundwater seepage into the pit and this will provide water for use in mine processes.

During extended wet periods, if one of the dewatering and environmental water storage dams reach their active storage capacity then the pits will provide temporary storage for surplus contaminated water.

2.1.6.1.4 Dirty water management system

Dirty water runoff from disturbed areas, such as overburden dumps, will be captured in sediment dams to encourage suspended solids to settle. Once settled, water will be transferred to environmental dams for reuse on site or if the storages have reached capacity it will be discharged to Lagoon Creek subject to water quality and release conditions. It is expected that during dry and median rainfall periods, sediment dam water will be reused on site and only released to the creek during prolonged wet periods. Water from the sediment dams will be moved around site (either for reuse or release) via a pump and pipeline system.

2.1.6.1.5 Groundwater management system

Groundwater will be extracted from the upper Permian coal measures using a borefield to minimise seepage into the pit. Bore water will be stored in environmental dams for reuse in various on-site processes. Bore water is expected to be of reasonable quality.

Product Finalisation date

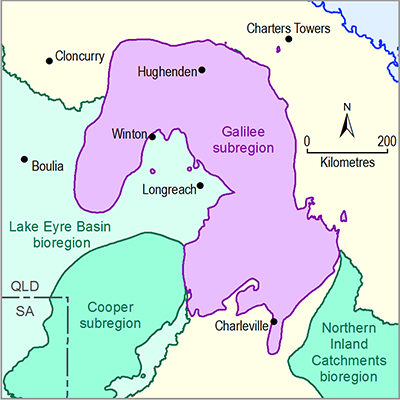

- 2.1.1 Geography

- 2.1.2 Geology

- 2.1.3 Hydrogeology and groundwater quality

- 2.1.4 Surface water hydrology and water quality

- 2.1.5 Surface water – groundwater interactions

- 2.1.6 Water management for coal resource developments

- Citation

- Acknowledgements

- Currency of scientific results

- Contributors to the Technical Programme

- About this technical product