- Home

- Assessments

- Bioregional Assessment Program

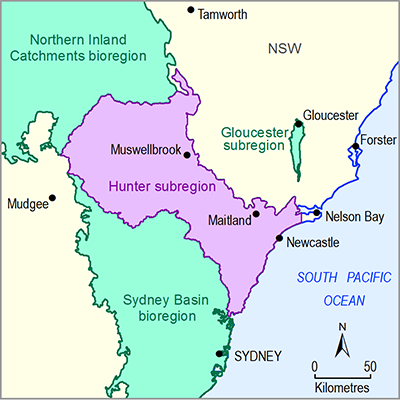

- Hunter subregion

- 2.3 Conceptual modelling for the Hunter subregion

- 2.3.4 Baseline and coal resource development pathway

- 2.3.4.2 Water management for coal resource developments

This section summarises the general characteristics of mine water management in the Hunter subregion in the context of the existing Commonwealth and NSW regulatory framework for managing on-site water to minimise impacts off site, as detailed in Table 12. It identifies the common elements that are important to inform the representation of the effects of mining operations on regional hydrology. It makes a connection between specific mine activities and the groundwater and surface water pathways that can lead to an off-site impact (discussed in more detail in Section 2.3.5). Mine-specific data used in the groundwater and surface water modelling such as start and end dates, mine footprints, flow rates, pumping depths, discharge rules, and surface water extractions, are provided in companion product 2.1-2.2 for the Hunter subregion (Herron et al., 2018a).

During all life stages of a mine from construction, production and through to mine closure and rehabilitation, the water balance of the mine site and surrounding areas can be affected. Changes at the land surface through clearing of vegetation and disturbance of top soil in developing the mine site, as well as changes in the fluxes of water between water stores during mine operations, have implications for the quality of water. In particular, the disposal of lower quality groundwater from worked seams has the potential to degrade the quality of receiving waters, for example, if discharged to the stream network. Runoff from areas disturbed at the surface can often be sediment laden and carry other impurities. Minimising the discharge of low-quality water to the wider environment and ensuring the mine has sufficient water of sufficient quality for on-site uses, whether that be for human consumption, coal washing, dust suppression or irrigation, are key objectives of mine water management.

In NSW coal mining began near Nobbys Head in Newcastle in the 1790s, with the first coal shipment leaving Newcastle in 1799 (NSW Minerals Council, 2016). Over that time policies, legislation and practices have developed to manage the impacts of mining developments both on and off the mine site. Mines are required to prepare mine water management plans that demonstrate how they will ensure their activities minimise the negative consequences on the environment from extraction and use of water, both in terms of quantity and quality of water. The policy/management context defines operating rules which can be used to inform the modelling of mine impacts. It is assumed that policies are adhered to and that generalisations about mine water management can be made that apply to all mines; however, this section notes any mines known to significantly depart from the generalisations.

The key legislation and policies that govern the management of water in relation to mining in NSW are outlined in Table 12. They are listed in the order in which they came into effect, although they will usually have had amendments since first enacted.

Table 12 Legislation and policies governing mine water management in the Hunter subregion

|

Legislation/Policy |

Agency |

Purpose and relevance to mine water management |

|---|---|---|

|

NSW’s Water Act 1912 |

DPI Water |

Under this Act, a licence or an approval is required by the mine:

|

|

NSW’s Environmental Planning and Assessment Act 1979 (EP&A Act) |

Department of Planning and Environment |

Mining developments classified as ‘State significant development’ (SSD), require preparation of environmental impact statements (EIS) / environmental impact assessments (EIA) as part of obtaining development consent. An EIS should include assessment of water related impacts. Extraction plans (formerly subsidence management plans) are required for underground mines that describe how subsidence will be managed to minimise impacts. |

|

NSW’s Mining Act 1992 |

Department of Industry, Resources and Energy |

Part 11 of this Act specifies the various requirements as well as conditions required to conserve and protect the natural environment (flora, fauna, fish, fisheries, scenic attractions, features of Indigenous, architectural, archaeological, historical, geological interest) as part of development consent. Also, specifies the conditions and requirements for rehabilitation of the mine sites. |

|

NSW’s Protection of the Environment Operations Act 1997 (POEO Act) |

Environment Protection Authority (EPA) |

Mining operations can produce polluted water and require an environment protection licence (EPL) under Schedule 1 of the POEO Act. An EPL authorises discharges to both surface waters and groundwater, and to land, and contains conditions relating to the concentration limits of those discharges, operating practices, discharge and ambient monitoring and reporting. The EPL may also specify requirements for pollution reduction programs (e.g. for site stormwater management). |

|

Commonwealth’s Environment Protection and Biodiversity Conservation Act 1999 (EPBC Act) |

Commonwealth Department of the Environment and Energy |

Provides the legal framework to protect and manage matters of national environmental significance. The 2013 ‘water trigger’ amendment empowers the Australian Government to approve, refuse and place water-specific conditions on large coal resource developments that are likely to significantly impact water resources. |

|

NSW’s Water Management Act 2000 |

DPI Water |

Under this Act, a licence or an approval is required by the mine:

|

|

NSW’s Protection of the Environment Operations (Hunter River Salinity Trading Scheme) Regulation 2002 |

Environment Protection Authority (EPA) |

Under this regulation, mines on the Hunter River below Glenbawn Dam and upstream of Singleton, require an EPL to discharge saline water to the Hunter River. |

|

NSW’s Aquifer Interference Policy (DPI Water, 2012) |

DPI Water |

Defines the regime for protecting and managing the effects of aquifer interference activities on NSW’s water resources. |

Data: DPE (2015)

The Commonwealth’s Environment Protection and Biodiversity Conservation Act 1999 (EPBC Act) empowers the Australian Government to approve, refuse and place conditions on actions that are likely to have a significant impact on matters of national environmental significance, including world heritage properties, national heritage sites, wetlands of international importance, Commonwealth marine areas, listed threatened species and ecological communities. In 2013, under the ‘water trigger’ amendment, the definition of matters of national environmental significance was expanded to include water resources, in relation to CSG and large coal mining developments. Thus, since 2013, approval is required from the Australian Government Minister for the Environment (now Minister for the Environment and Energy) if a proposed development is likely to have a significant impact on water resources. Guidelines were published in late 2013 to assist coal mining proponents to decide whether an impact is likely to be significant (Commonwealth of Australia, 2013).

Projects that are deemed likely to have a significant impact on water resources are referred to the Independent Expert Scientific Committee (IESC), established in 2012 to provide scientific advice to the Australian Government Minister for the Environment and State regulators on the impacts of proposed large-scale developments on matters of national significance. BAs, such as this one for the Hunter subregion, are being undertaken to strengthen the science underpinning decision-making around actions that are likely to significantly impact water resources.

Prior to this, mine water management was predominantly a state matter. The other legislation and policies listed in Table 12 are NSW regulatory instruments for protecting water resources and water-dependent assets in NSW from developments, including CSG development and coal mining. NSW’s Mining Act 1992 makes provision for the protection of the environment in the course of mining. The definition of environment encompasses ecological and sociocultural assets, which are in or on the land over which authority or claim is sought (Part 11, section 237(1)). Under this Act, the Minister may require environmental impact studies to be carried out.

Under NSW’s Environmental Planning and Assessment Act 1979, major developments, including mining, must prepare environmental impact statements (EIS) / environmental impact assessments (EIA) detailing the impacts to natural and human environments and the options to minimise damage for consideration by the regulatory authority and the public in making a determination. Mining EIAs must assess the changes to surface water and groundwater and include a mine water management plan and rehabilitation planning documents, which satisfy the Minister that the impacts of the mine on water resources during and following mine closure are minimised. For underground operations, modern development consents require the preparation of an extraction plan that describes how impacts of subsidence will be managed to meet the requirements of the development consent. With respect to water resources, these extraction plans are particularly concerned with identifying and managing the risks to surface water courses and alluvial aquifers, but may also consider effects on drainage more generally through interception of rainfall and runoff in subsidence-induced depressions.

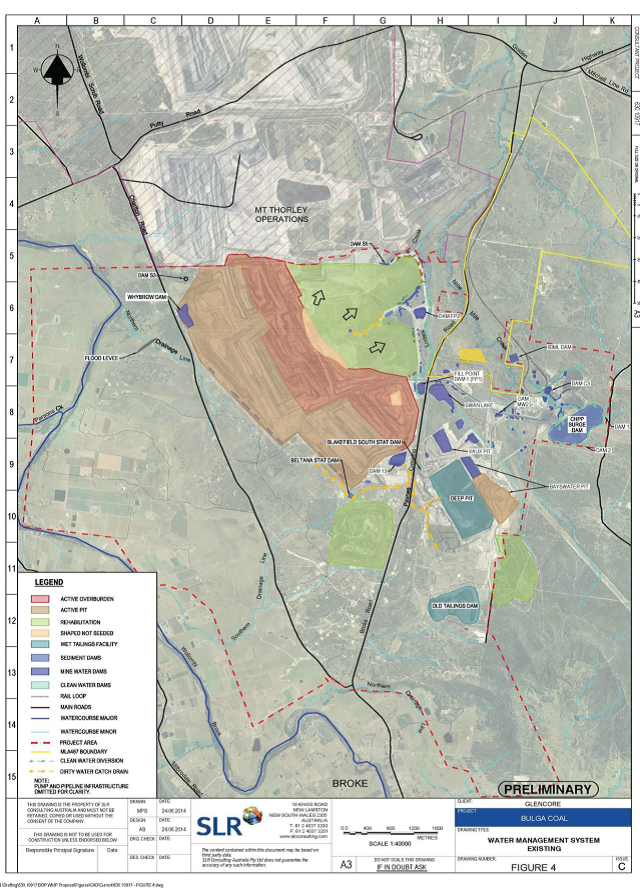

A typical mine water management plan in the Hunter subregion provides details of expected pumping rates from the open-cut or underground workings, runoff diversions and on-site water storage, discharge locations to the river network, on-site water treatment, requirements for clean water and post-mining hydrology following rehabilitation. Figure 20 illustrates the mine water management system for the Bulga Coal Complex, which comprises both open-cut and underground operations. It includes a combination of permanent structures that will continue to operate post closure and temporary structures that will only be required until the completion of rehabilitation works. Various components of water management at the Bulga Coal Complex are:

- four main water storage areas (Vaux Pit, Bayswater Pit, Coal Handling and Preparation Plant (CHPP) Surge dam and Dam 13) with total storage capacity of up to approximately 5400 ML

- Dam C3 with capacity of 21 ML to capture surface runoff from coal handling process plant, workshops, run of mine (ROM) pad areas

- clean water catchment areas upstream of mining with diversion channels. Water is collected and pumped to an unnamed tributary of Nine Mile Creek

- sediment dams to collect surface water runoff from mine disturbance areas and transferred to main storage areas through pipelines

- discharge locations under the Hunter River Salinity Trading Scheme (HRSTS)

- proposed and current mine rehabilitated areas in order to repair the impact of mining on the environment.

For modelling the effects of mine developments on regional scale hydrology, the specifics of water movements on site are not necessary. Instead it is the changes in fluxes to and from the site as a consequence of mining development that need to be quantified and spatially represented.

Figure 20 Bulga Coal Complex water management system

This figure is not covered by a Creative Commons Attribution licence. It has been reproduced with the permission of Glencore.

The following generalisations are used to inform hydrological modelling of the Hunter subregion. They reflect regulatory requirements relating to mine site water management and are assumed to be reflected in practice. Details of the numerical model development and the modelling assumptions that relate to the representation of the hydrological changes from coal resource development can be found in companion product 2.6.1 (Zhang et al., 2018), companion product 2.6.2 (Herron et al., 2018b) and companion product 2.1-2.2 (Herron et al., 2018a) for the Hunter subregion.

- Mine working areas are largely isolated from the wider surface water drainage network early on in the development process through construction of diversion drains.

- Rain that falls on the mining area is retained on site.

- Groundwater pumped from mine workings is retained on site, unless the mine has an environment protection licence (EPL) which entitles it to discharge it from site. Managing mine water make to minimise pollution of surface water and groundwater resources is a key aspect of site water management. Retained water is used on-site for mine and coal processing water requirements or, in some cases, irrigation (e.g. Ulan). It may need to be treated for other uses. Ultimately it is lost to evaporation and seepage.

For surface water modelling, the foregoing are interpreted to mean that all runoff generated on site, including from undisturbed areas, which are intercepted by a mine dam, is retained on site. For groundwater modelling, mine water make is only discharged to the river if the mine has a licence to do so. The modelling ignores unintended spills and leakage from on-site storages, which are assumed to be sufficiently dealt with through the approvals process and conditions imposed on mine-site operations. For river modelling purposes, rules to reflect the operation of the HRSTS need to be incorporated into the model construction.

- At mine closure following open-cut mining, a void is left in the final landform, unless stated otherwise in mine rehabilitation plans.

This is traditional practice, particularly for mines with low overburden to coal ratios (such as those in the Hunter Valley). The void acts as a local sink for both surface water and groundwater, and if the void is large enough, the evaporation will continue to drive the groundwater flow into the void and the local and regional groundwater may never fully return to pre-mining conditions (Mitchell, 2009). Leaving final voids is an increasingly controversial practice, and the requirement for mines to undertake complete rehabilitation of open-cut mines is probably becoming more common. Companion products 2.1-2.2 and 2.6.1 for the Hunter subregion (Herron et al., 2018a; Zhang et al., 2018) provide details of how final voids are specified in the surface water modelling.

- Rehabilitation of open-cut mined-out areas is typically progressive, with worked areas being infilled, landscaped and re-vegetated as the pit faces advance. Thus, the hydrological changes from mining disturbance can vary over the life of mine. However, the normal practice is for surface water diversions to be removed and drainage returned to a pre-disturbance state at the end of mining whenever and wherever this is possible (DITR, 2006).

For modelling purposes, rehabilitation is assumed to commence following the cessation of mining (rather than represented progressively) and the effects of mining on surface water are sustained for a defined period, before being reduced over time to a pre-disturbance level.

The amount of runoff retained on site will vary significantly between open-cut and underground mine operations. Generally, a larger surface area is disturbed during open-cut mining than for underground mining; thus, there will be bigger changes in surface water hydrology from open-cut mines than from underground mines. However, underground mines can cause subsidence at the land surface and changes in the hydraulic properties of subsurface layers, leading to increased interception of runoff in the area of subsidence. Since mining consent in NSW is contingent on minimising the negative effects of subsidence, as specified through an approved extraction plan, for modelling purposes the reduction in surface runoff from areas above longwall mines is assumed to be 5% during and following the cessation of mining. Details are reported in companion product 2.6.1 for the Hunter subregion (Zhang et al., 2018).

In NSW, surface water extracted from rivers and used on site has to be licensed under NSW’s Water Act 1912 or NSW’s Water Management Act 2000. Extractions from the stream network are modelled in the Australian Water Resources Assessment river model (AWRA-R), based on patterns of extraction for irrigation and mining from NSW DPI Water. Details are provided in companion product 2.6.1 for the Hunter subregion (Zhang et al., 2018).

Similarly, the removal of groundwater from mine workings and extractions of groundwater from production bores have to be licensed under the NSW Water Act 1912 or NSW Water Management Act 2000. The amount of groundwater extracted from mine workings can vary significantly between mines, depending on the hydrogeology of the worked area, including volumes of stored water and hydraulic conductivity and connectivity between the different stratigraphic layers. Modelling of groundwater changes, undertaken by the mining companies as part of their EIAs, is used to estimate likely flow rates and requirements for water access licences. Flow rates (licensed volumes of water pumped from the mine workings) have been obtained from mine water management reports for each mine represented in the baseline and CRDP in the groundwater model (see companion product 2.6.2 for the Hunter subregion (Herron et al., 2018b)) and are provided in companion product 2.1-2.2 for the Hunter subregion (Herron et al., 2018a).

Groundwater pumped from the mine workings is often of lower quality than surface water. In the Hunter subregion this can be due to the marine origins of the groundwater and/or the accumulation of leachates as recharge water percolates the regolith and rock formations. Discharges of low quality water from mining operations need to be managed carefully. NSW’s Protection of the Environment Operations Act 1997 (POEO Act) protects the quality of the environment in NSW from pollution. Mining, coal working and coking are scheduled activities under this Act and require an environmental protection licence (EPL) to discharge off-site. The NSW Environment Protection Authority, who administers the Act, can stipulate the conditions relating to pollution prevention and monitoring on mine sites as part of their EPL, including:

- mine water discharge volumes to water bodies (such as lakes, river, creeks) and land

- concentration limits for various water quality parameters for discharge mine water

- site water management operating practices

- discharge and ambient monitoring and reporting.

To ensure that discharges to the river do not exceed specified thresholds, mines may have to treat low quality water to the required standard prior to discharge. Not all mines will necessarily have an EPL to discharge water. Without a licence, discharges to the stream network are not permitted.

In the Hunter river basin, the POEO (Hunter River Salinity Trading Scheme) Regulation 2002 was enacted to specifically manage the potentially large volumes of low water quality discharges from the high concentration of industrial developments in the regulated part of the Hunter River between Glenbawn Dam and Singleton. It provides for discharges of mine water off-site during periods of high river flow. Under the regulation, mines and power stations within the HRSTS area are required to purchase credits under licence from the NSW Environment Protection Authority to discharge saline water to the Hunter River. There are a total of 1000 salt discharge credits in the scheme, 200 of which expire every two years and are redistributed via public auction. Credit holders (mines and power stations) and their credits as of 23 February 2016 are listed in Table 13. Flows in the Hunter River are notionally divided into blocks, a body of water that flows down the Hunter River that is predicted to pass through the lower sector reference point (gauging station at Singleton) in a 24-hour period. During high flow, each participant is entitled to discharge a share of the total allowable discharge on each block according to the number of salt credits they hold. The AWRA-R model used in the Hunter BA to model Hunter River flows incorporates rules to represent mine discharges under the HRSTS (see companion products 2.1-2.2 and 2.6.1 of the Hunter subregion (Herron et al., 2018a; Zhang et al., 2018)). Coal resource developments, such as the proposed Bylong mine, and the Moolarben, Wilpinjong and Ulan mines, which are upstream of Kerrabee in the Goulburn river basin and are not part of the Hunter River Salinity Trading Scheme, require an EPL under the POEO Act 1997 to discharge off site.

Table 13 Hunter River Salinity Trading Scheme licence holders and credit allocations (as of 23 February 2016)

Data: EPA (2016a)

This table lists the name of the Hunter River Salinity Trading Scheme (HRSTS) participants as given on the NSW Environment Protection Authority’s HRSTS website and they may not be the mine name.

Some examples of EPL conditions attached to mines in the Hunter subregion are provided to illustrate differences between Hunter River Salinity Trading Scheme (HRSTS) participants and non-HRSTS mines:

- Bulga Coal Complex operates under EPL 563 (Glencore, 2015) and is part of the HRSTS. As per EPL 563, pH of mine water discharge should be between 6.5 and 9.5 and concentration of total suspended solids (TSS) should be less than 120 mg/L. The discharge under the HRSTS from Dam 3 and CHPP Surge Dam should not exceed 55 ML/day and 130 ML/day respectively (EPA, 2016b). Locations of surface water monitoring points, frequencies and parameters to be recorded at the discharge points are also stipulated in the EPL.

- Hunter Valley Operations operates under EPL 640 and is part of the HRSTS. EPL 640 requires that the pH of discharge mine water be between 6.5 and 9.5; TSS concentrations should be less than 120 mg/L at discharge points 3 and 4; and the electrical conductivity of water should be less than 400 µS/cm at discharge point 5. Allowable discharge volumes under the HRSTS range from 100 ML/day (Point 3) to 130 ML/day (Point 4), and 7 ML/day to alluvial lands (EPA, 2016c). Locations of surface water monitoring points, frequencies and parameters to be recorded at the discharge points are also stipulated in the EPL.

- Ulan Coal Mine operates under EPL 394 and is not part of the HRSTS. The EPL specifies seven discharge points, including three discharge locations for Ulan Creek and one for land (irrigation) (EPA, 2016d). In EPL 394, concentration limits for pH, iron, zinc, oil and grease, TSS and discharge volumes at various points to land (irrigation), unnamed watercourse and Ulan Creek were stipulated. Locations of surface water monitoring points, frequencies and parameters to be recorded during discharge events at the discharge points are also stipulated in the EPL 394 for Ulan Coal Mine.

Mines that are not part of the HRSTS can trade their saline water with the HRSTS credit holders through a water sharing agreement. Examples are:

- Drayton Mine, which does not have any EPL to discharge mine water to the river, but has a water sharing agreement with Mount Arthur Coal Mine to transfer up to 600 ML/year of excess mine water (Anglo Coal, 2010).

- Ashton Coal Mine, which does not hold an EPL for discharging mine water, but has a water sharing agreement with the Glennies Creek Mine (now called Integra) for the supply of up to 900 ML/year of mine water from the operations (Ashton Coal, 2015).

- Hunter Valley Operations, a HRSTS participant, which has a water sharing agreement to transfer water to and from Liddell (Glencore) and Wambo (Peabody) mines (Rio Tinto, 2015).

Water transfers between mines owned by different companies are managed through formal agreements. Transfers of water between mines operated by the same company do occur. These movements of water are not regulated by the Environment Protection Authority. For assessing regional-scale hydrological changes, these transfers are assumed to be water retained on site.

This section has provided an overview of the regulatory framework governing mine water management in the Hunter subregion and identified the key elements needed to inform representation of hydrological effects of mines in the quantitative modelling in companion products 2.6.1 and 2.6.2 for the Hunter subregion (Zhang et al., 2018; Herron et al., 2018b).

Mine-specific water management data, used to represent individual mines in the modelling, are detailed in Section 2.1.6 of companion product 2.1-2.2 for the Hunter subregion (Herron et al., 2018a).

Product Finalisation date

- 2.3.1 Methods

- 2.3.2 Summary of key system components, processes and interactions

- 2.3.3 Ecosystems

- 2.3.4 Baseline and coal resource development pathway

- 2.3.5 Conceptual modelling of causal pathways

- Citation

- Acknowledgements

- Currency of scientific results

- Contributors to the Technical Programme

- About this technical product